Thermal Research Centre (TRC), Nagpur

Thermal Research Centre is pioneer in carrying out Condition assessment,Remaining Life Assessment, Renovation & Modernization, Life Extension studies and Non Destructive Evaluation (NDE) of Power Utilities and Industries equipment like Boilers, Turbines, Condensers etc., Material characterization & failure analysis, Condition assessment of RCC and steel Structures.

Our team comprises of Doctorates, Post graduates engineers having various ASNT NDT Levels with vast experience in Power sector.

OBJECTIVESOF THERMAL RESEARCH CENTRE:

- To study operation and maintenance problems of Power Stationsand provide proper solution to increase the efficiency.

- To solve all problems related with Mechanical & Metallurgical in Thermal, Hydel Power Plant and other industries

- Applied research in power generation

- Rendering consultancy and field testing services to Power Utilities and Industry

- Energy conservation in power plants and improvements in efficiencies of combustion auxiliaries and interconnected systems.

- Conduct Seminar/ Conference/ Workshop/ training programs for up gradation of technical skills for Power Utilities and Industry

- Work in line with ISO 9001-2015

- As a recognised research centre by RashtrasantTukadojiMaharaj Nagpur University (RTMNU), Nagpur, Maharashtra providing support to M.Tech and PhD scholars for pursuing their research.

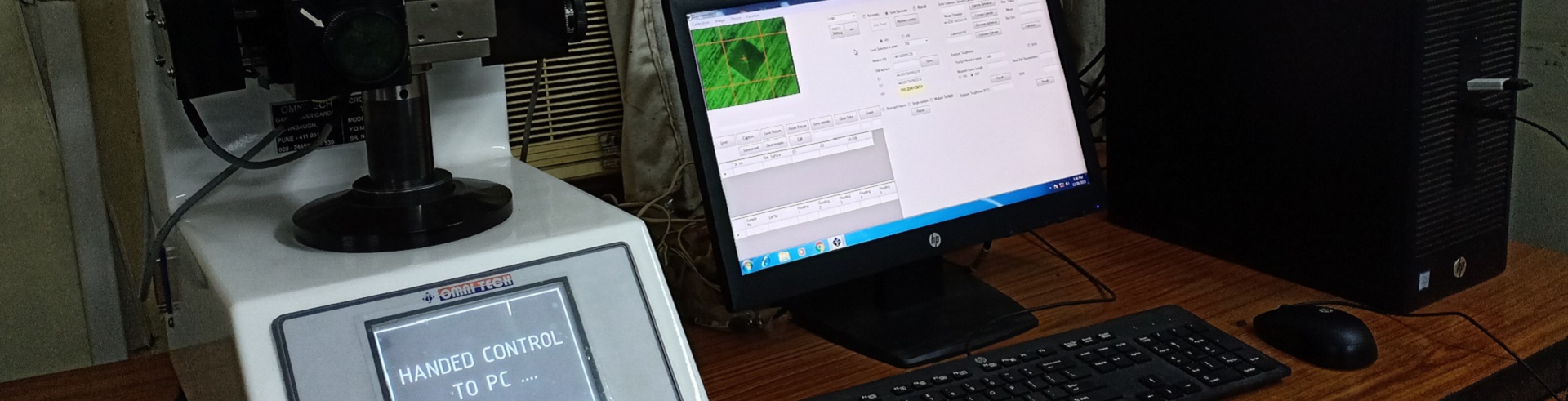

FACILITIES AVAILABLE AT TRC:

- Non Destructive Evaluation (NDE), Remaining Life Assessment (RLA), Renovation &Modernisation (R&M) and Life Extension studies of power Utilities & Industry equipment like Boiler, Turbine, and Condenser etc.

- Investigation study for root cause analysis on boiler tube/ turbine component failure of Power Utilities and Industries.

- Performance evaluation of high temperature materials used for stress corrosion, fatigue and creep and material conservation.

- Finite element analysis of plant components

- Mechanical test e.g. tensile, flattening etc. for ascertaining material properties.

- Condition assessment of RCC and Steel structures of Power Utilities and Industries

- Methodology for Strengthening and restoration of Civil structures of Power Plants and other utilities based on Non-Destructive Testing’’

- Hot spot measurement in Boilers, Switch yards, transformers etc.

CREDENTIAL OF TRC

- Certificate of approval of “Well Known Remnant Life Assessment Organisation” by Central Boiler Board, Govt. Of India.

- ISO 9001:2015 for Consultancy Activity.

- Recognised “Research Centre” by RashtrasantTukadojiMaharaj Nagpur University (RTMNU), Nagpur, Maharashtra.

SERVICES OFFERED TO POWER SECTOR AND OTHER INDUSTRIES:

- Consultancy in operational and maintenance problems of thermal power generation, RLA, R&M

- Condition assessment and Residual Life Assessment of all types of Boilers ranging from process Steam Boiler to 660 MW capacity, Waste Heat Recovery Boilers, Gas and combined cycle Power Plant components, Steam turbine and Hydro turbine.

- Renovation & Modernization and Life Extension studies of Boilers, Turbines and other plant equipment.

- Failure Analysis of Power Plant Components.

- Investigation study for root cause analysis on boiler tube failure (BTF).

- Low cycle thermal fatigue damage assessment of steam turbine.

- Health Assessment / Condition Assessment of Condenser Tubes.

- In-situ material mix up studies of boiler area and turbine area of different power plants and process industries.

- In-situ oxide scale thickness measurement of boiler tubes for different power plants and process industries.

- Hydrogen embrittlement test of water wall tubes of boiler

- Fibroscope based remote video based inspection of boiler and turbine components

- Thermography studies in various plants

- Corrosion studies of star column of boiler structure.

- Detection and sizing of flaws (e.g. cracks) in complex geometric plant components.

- Condition assessment and end of functional service life Evaluation of RCC and Steel structures of Power Utilities & Industry.

- Third party Inspection of passive fire protection systems.

RESEARCH &DEVELOPMENT, DEMONSTRATION AND PILOT SCALE STUDIES ON:

- Performance evaluation of high temperature materials used for stress corrosion, fatigue, creep and materials conservation.

- Flaw characterization by ultrasonic time of flight diffraction (TOFD) technique.

- Damage assessment in boiler tubes, drums and headers.

- Condition assessment of complex geometry power plant components by ultrasonic TOFD technique.

- Low cycle thermal fatigue damage assessment of steam turbine during transient.

- Development of Heat pipe for transfer of Heat energy.